Everyone has heard the term “Safety Is No Accident”. And if your company has ever had an “Accident” or injury, the question is, where was “Safety”? Some companies have a safety program while other companies rely on their good luck. However, when an accident happens, it costs everyone a lot of money and time and challenges the company’s safety program.

Everyone has heard the term “Safety Is No Accident”. And if your company has ever had an “Accident” or injury, the question is, where was “Safety”? Some companies have a safety program while other companies rely on their good luck. However, when an accident happens, it costs everyone a lot of money and time and challenges the company’s safety program.

By definition, an “Accident” is an unplanned event and “Safety” is the process of protecting against accidents. Thus, if you plan for safety, the goal is to prevent the unplanned accidents. Accidents can still happen, however, only through a good safety program can your company hope to prevent unplanned accidents from happening.

This is where Bay Environmental Strategies, Inc. comes in. We are an environmental, health & safety consulting firm that dedicates its knowledge and experience in developing and managing safety programs for all types of businesses. Our safety professionals will conduct a hazard assessment in your company and then tailor a safety program to meet your specific regulatory compliance needs. Whether it’s the Department of Transportation (DOT), the Occupational Safety & Health Administration (OSHA), the Mine Health and Safety Administration (MHSA) or the Wisconsin Department of Natural Resources (WDNR) regulations, we can assist your company in the development, implementation and management of your overall safety program. We can help you manage your current safety program or assist your company in the development of a new safety program.

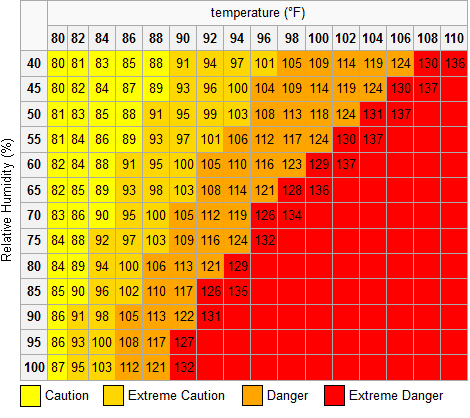

Every company needs a safety program. Whether you’re an office environment, manufacturing, service or transportation company, you need to have a safety program to identify the hazards within the organization and then have policies and procedures in place to control and manage these hazards. Most regulatory agencies require company’s to have policies, procedures and programs in place to protect the safety of their employee’s and workers. If you do not have a safety program, you are merely gambling with accidents and injuries. And it’s only a matter of time before your employee’s, insurance company, regulatory agencies, or your customers demand that you implement a safety program.

Why wait for the worst to happen. Give Bay Environmental Strategies, Inc. a call and see how we can help your company implement or manage a safety program in a very cost effective manner. Some of our services include:

- Hazard Assessments

- Job Site Safety Inspections

- Written Health & Safety Manuals

- Written Policies, Procedures and Programs

- Facility Audits and Inspections

- Training Programs

- Safety Meetings

- DOT, OSHA or WDNR Representation

- Accident & Injury Investigation

- Safety Committee Representation

To receive a “Free” hazard evaluation and proposal, please contact Gene Olesen or Rachel Vincent at Bay Environmental Strategies, Inc. at 920-347-2234 or email at golesen@bayenvironmental.com or rvincent@bayenvironmental.com.